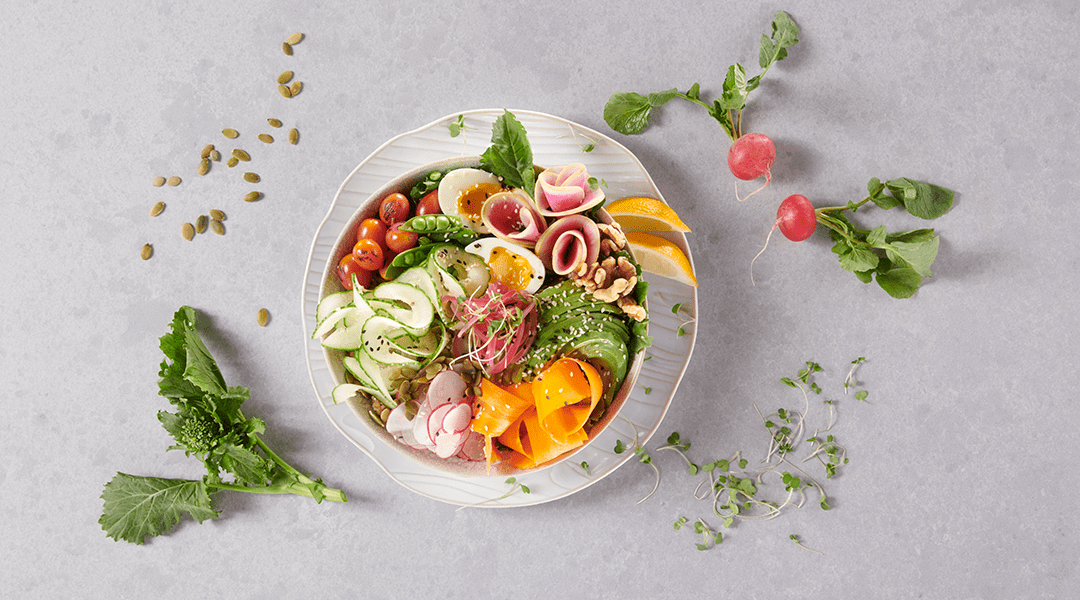

Elevate Your Tastebuds

In every corner of the world, flavor is the heart of culture and cuisine. It’s infinite, expressive, and ever-evolving—just like you. So we searched high and low for the greatest flavors on earth, and carefully crafted them into hundreds of innovative and mouthwatering rubs, blends, fusions, and more that take your food (and your stories) boldly forward. Trade East offers over 100 of the finest spices, seasonings, rubs and blends, all MSG-free, so you can deliver authentic flavors of the world to your customers.

Your Sauce's New Best Friend

Trade East X Melinda’s. The ultimate collaboration of flavor.

Trade East is teaming up with Melinda’s to bring variety to your menu with only a few drops. Just a dash of a liquid spice takes your recipe from average to outstanding. Transform tastes and enhance flavors without putting in extra work or spending more on ingredients.

Milled and Packaged to Preserve Quality

Trade East Spices & Seasonings are cryogenically milled. Cryogenic milling mitigates heat, moisture and light, three factors that can cause deterioration. Before milling, Trade East Spices & Seasonings are thoroughly cleaned and run through a stringent quality assurance process, ensuring only the most worthy ingredients are packaged. Each product is sealed to preserve flavor and aroma—the heart of the product. Each package has a tamper-evident seal to ensure safety and enhance shelf-life for quality you can count on time and time again.

Globally Sourced

Options for Every Foodservice Operation

Trade East offers a variety of flavors so you can meet today’s taste preferences and health-conscious demands while helping your foodservice operation stand out. The 100-plus products in our collection include:

- Cuisine-oriented varieties (i.e., Italian, French, etc.)

- Kitchen staples

- Salt-free seasonings

- Trend-forward rubs

- Smoky solutions

- Spicy selections

- Globally infused options

Taste Trade East for Yourself

Talk to your sales rep about sampling a selection of Trade East Spices & Seasonings.

Not a customer, but interested in Trade East? Fill out the form below and we’ll be in touch.

Let’s Talk About Your Needs

Our purpose is to serve our customers with the highest quality foodservice products and services. We achieve this purpose through innovative systems and the spirit and integrity of our people.

You want to feed people. We’re here to help. Let’s talk about how.